Centrifugal compressors are also similar to centrifugal pumps of the style shown in the adjacent figures.

Centrifugal air compressor definition.

At the impeller outlet tip it will gain the energy by transfer of angular momentum by the rotating action of impeller blades.

A centrifugal compressor is capable of delivering high flow capacity of gas per unit of the space and the weight.

Comments are also made on how to measure power consumption.

A centrifugal compressor is a device that has impeller blades set into it.

This compressor is used to transfer energy using the impeller blades that rotate to create a centrifugal force.

The air is then discharged through a diffuser where the.

Air will come out from the impeller i e.

A centrifugal air compressor is a member of the dynamic type compression technology.

Energy will be added to the impeller and when working fluid i e.

A centrifugal compressor is a type of dynamic compressor or turbocompressor with a radial design.

Examples of how to use centrifugal compressor in a sentence from the cambridge dictionary labs.

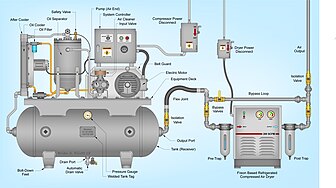

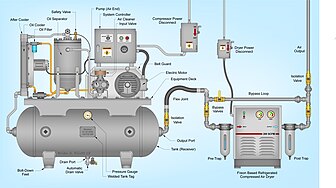

Impeller and diffuser are two very important parts of a centrifugal compressor.

This article is not intended to be an engineering discussion of the various types and designs of centrifugal and other air compressors.

The key difference between such compressors and pumps is that the compressor working fluid is a gas compressible and the pump working fluid is liquid incompressible.

In general this article focuses on the definitions of terms often used to understand centrifugal air compressor performance.

Choke and surge occur at the extreme ends of the performance curve and should be avoided.

Compressor capacity should be stated at plant conditions which are actual cubic feet per minute acfm.

Unlike displacement compressors that work at a constant flow dynamic compressors work at a constant pressure and the performance is affected by external conditions such as changes in inlet temperatures.

In dynamic compression air is drawn between the blades on a rapid rotating compression impeller and accelerates to high velocity.

Centrifugal air compressor basics key concepts centrifugal compressors are most effective when running at full capacity.

Although manufacturers that require over 200 to 250 total horsepower tend to realize the greatest savings all industrial manufacturers should consider the advantages of.